Selecting the proper Orton Pyrometric cones

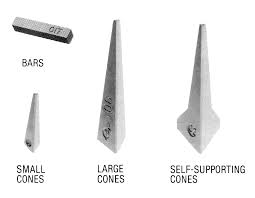

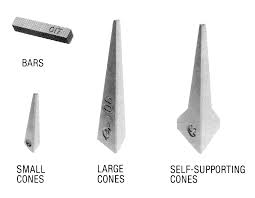

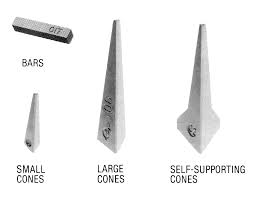

Utilize the Orton Cone Temperature Equivalents Chart to select the correct cone numbers you will need. Selecting Orton’s self-supporting cones will solve the issue of correct mounting height and angle for you. For further assistance selecting the proper cone, see “Selecting Cone Types” under “PYROMETRIC CONES-RESOURCES”.

Example: You are firing to 1,147°C and the heating rate for the final 100°C is 75°C/hr. Select the heating rate column closest to your rate, which is 60°C, you scan down to 1,147°C, which is greater than the temperature equivalent for cone 2 and less than the temperature equivalent for cone 3, therefore your target cone should be cone 3. If your firing profile includes a soak at the maximum temperature then you should increase the target cone by one to two cone numbers for a one hour soak and two to three cone numbers for a soak of two hours.

Once you have defined the cone number you need for your kiln’s firing profile initially you should select one cone number above and one cone number below your target cone. Fire a test of the three cones in your kiln to determine the exact fit to your firing profile.

Now it is time to put the cones to work for you. To evaluate heat work uniformity with your kiln place the three cone series at the equivalent of top, middle and bottom, right, center and left and evaluate the cones’ degree of bending at each location. This process should help you identify any hot or cold spots within your kiln setting. The second use of the cone is for quality assurance of the firing process. On a routine basis run the three cones at predetermined locations, top middle and bottom in the center of the ware. A brief look at these cones on a routine basis will provide verification of consistent heatwork delivery to the ware and also provide an early warning if changes in the firing profile are occurring. Keeping a written log or digital photo of each firing’s cone positions will provide a reference for future kiln performance and help you recognize changes in the firing profile before they become major problems.